Picking proper sauce bottling equipment should be a top priority for any business wanting to streamline their sauce production process, taking quality end product as a main factor as well. With so many sauces on the market today - everything from ketchup and mustard to gourmet pasta sauces -choosing the correct equipment can be difficult. Today, I will outline significant factors for your take in building the perfect solution tailored for your production needs.

Assess Your Sauce Viscosity

The viscosity of your sauce will have a big effect on the kind of bottling equipment you will require. They go from thin and runny to thick and chunky (like hot sauce to salsa or relish). There are piston fillers desired for thick, chunky or pasty products like high-viscosity sauces. On the other hand, that consistent fill level provided by overflow fillers is perfect for thinner sauces, where the product would otherwise find different levels during filling due to slight variations in the bottles.

Consider Production Capacity

Anything that impacts your production volume will effect what sort of bottling equipment you should be using. If you are manufacturing sauce at scale then you will want a mechanism that can go fast but not lose too much accuracy. Others can handle as many as 120 bottles per minute, making them well-suited to higher volume production lines. Smaller artisanal producers could make do with a semi-automatic system that can manage 10-50 bottles per minute.

Check Container Compatibility

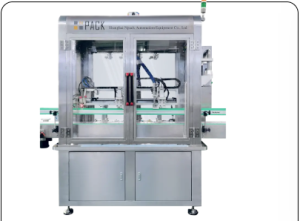

The type of containers for your sauce may also determine the type of bottling equipment that you would be using. These machines are design to suit different sizes and shapes of containers. The equipment you choose should be able to handle the style of jars or bottles you use, taking note of both the jar's opening size and the container itself (glass vs. plastic, for example). This compatibility is critical to prevent a spillage and effective bottling.

Seek Out Customization And Adaptability

The selection of bottling equipment is based around flexibility. Select machines with simple changeovers from different types of sauces or bottle sizes. If you plan to expand your product range, this is particularly important. Further more, equipment with configurable settings, e.g. filling speed and volume, can be adjusted depending on production requirements.

Look Out for Hygiene and Maintenance Features

Hygiene plays a critical role in food production. Select one of easy to clean and maintain Sauce bottling equipment. Doing so can help you use this cool espresso machine as a long-term solution as the stainless steel parts are well-built and resistant to corrosion and can be easily sanitized. Equipment that has less or no dead zones where sauce can hang out and horizontal parts are less prone to contamination and easier to clean as well.

Ensure Durability and Support

It is important that there is durability in the equipment and this should be the topmost on the list of consideration. This can also be accomplished by using machines that are designed to be heavily used in a production environment. Additionally, factoring in the sum of technical help and service may be helpful. After-sales support that keeps your production line running and minimises downtime.

Budget Considerations

And last but not least, take into account your budget. Although it may be more cost-effective to choose low-end hardware, spending money on top of the line equipment that is designed to last for years will be cheaper in the long run as you avoid unnecessary downtime. Think about the whole cost of ownership, like spending on maintenance and operation, not just the purchasing costing upfront.

The suitability of your sauce filling equipment will have an effect on the productivity, efficiency and quality levels of your production line and must, therefore, be an informed choice. With these factors in mind, you can choose equipment that is capable of meeting your specific requirements, and allow you to further grow and succeed in your business.